Get Quotes for Microbial Cell Disruption Equipment from Top Exporters in China

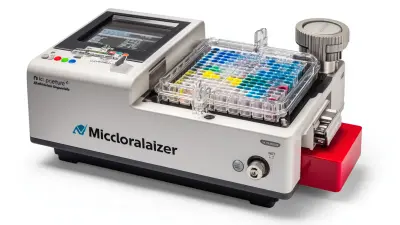

In the domain of microbial cell disruption, MGTTA LABORATORY EQUIPMENT Co., Ltd. stands out with its exceptional products tailored for the Chinese market. Our advanced equipment facilitates efficient cell lysis, optimizing the yield of intracellular components like proteins and metabolites. Offering a diverse range of robust solutions for bacteria, yeast, and fungi, each device is engineered with precision to cater to various applications, from research labs to industrial settings. With a commitment to quality and reliability, MGTTA's products are ideal for enhancing laboratory workflows. Our dedicated team is here to provide outstanding customer support, ensuring you find the optimal solutions for your microbial disruption needs. Enhance your production efficiency and research outcomes with our state-of-the-art equipment.Why Choose Microbial cell disruption Manufacturer Factory

When it comes to sourcing high-quality microbial cell disruption equipment, choosing the right manufacturer is crucial for global procurement teams. MGTTA, an international trading company founded in 2022, specializes in laboratory equipment, medical devices, and chemical plant machinery, bringing cutting-edge technology to industries worldwide. Our factory stands out not just for the quality of our products, but for our unwavering commitment to innovation and customer satisfaction. One of the key reasons to choose MGTTA as your microbial cell disruption manufacturer is our dedication to quality assurance. We utilize state-of-the-art technology and adhere to stringent manufacturing standards, ensuring that our products meet the highest international benchmarks. Additionally, our experienced team works closely with clients to customize solutions that fit specific requirements, providing a level of flexibility not commonly found in larger suppliers. Moreover, MGTTA recognizes the importance of sustainability in today’s market. Our manufacturing processes are designed to be environmentally friendly, reducing waste and energy consumption while delivering efficient and reliable products. By partnering with MGTTA, you not only gain access to premier microbial cell disruption technology but also contribute to a greener future for our industries. Elevate your operations with MGTTA, where cutting-edge science meets global responsibility.

Why Choose Microbial Cell Disruption Manufacturer Factory

| Criteria | Advantages | Considerations |

|---|---|---|

| Quality Standards | Adherence to GMP and ISO standards ensures product reliability. | Check certification validity and compliance history. |

| Technology | Utilization of advanced disruption techniques improves yield. | Evaluate the impact of technology on your specific applications. |

| Customization | Tailored solutions can optimize processes for different microbial strains. | Clarify customization capabilities before engaging. |

| Cost Effectiveness | Competitive pricing can reduce overall production costs. | Assess total cost of ownership including maintenance and support. |

| Support and Service | Reliable customer support enhances operational efficiency. | Determine the availability and responsiveness of support services. |

Why Choose Microbial cell disruption Products Factory

M

Matthew Hall

Quality beyond compare! Their support team provided excellent guidance and assistance.

29 May 2025

G

Gabriel Campbell

The quality is exceptional! The customer service was friendly and very professional.

12 May 2025

S

Samuel Bin

The product quality is remarkable! Great follow-up service from their knowledgeable staff.

28 May 2025

J

John Smith

The quality of the product exceeded my expectations. The after-sales service team was incredibly professional and responsive.

23 June 2025

E

Emily Roberts

The after-sales service was top-notch. The staff was knowledgeable and addressed all my concerns promptly!

24 June 2025

A

Amy White

The after-sales support was impressive. I felt valued as a customer throughout the process!

07 June 2025